PTFE Hose Assemblies

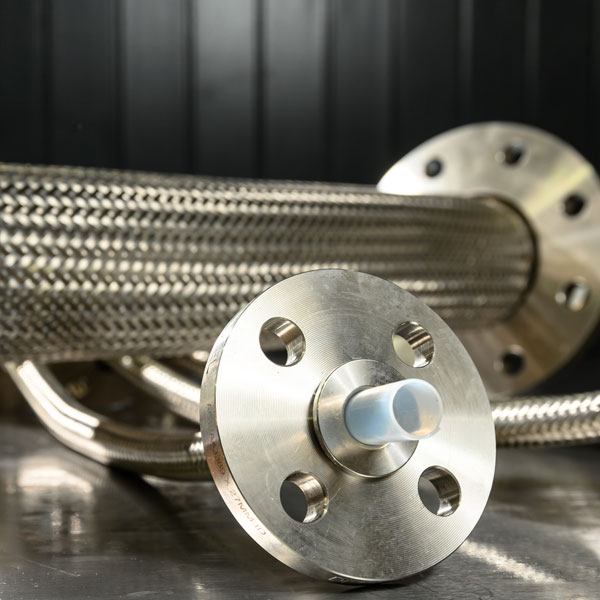

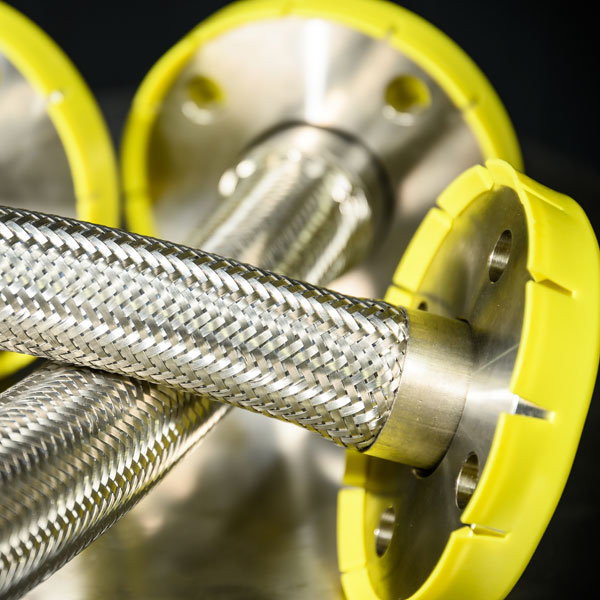

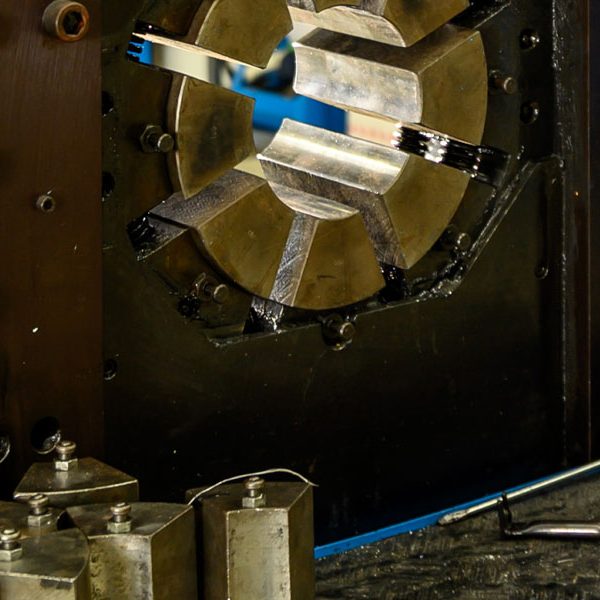

We manufacture and stock a huge variety of hoses, ferrules and fittings and can produce the ideal lined PTFE hose assembly to meet the requirements of your project. Our team of PTFE specialists are skilled in all aspects of assembly—from production and testing, through to certification and traceability. We manufacture lined PTFE hose assemblies to the exact specifications the customer requires, accommodating even the most bespoke customer needs.

Polymer braid (polybraid) supports and protects the hose’s inner PTFE layer while offering greater flexibility and lighter weight than its stainless steel counterpart. Polybraid hose assemblies are most suitable for low-pressure applications and are particularly appropriate for the transfer of media that is not compatible with stainless steel braid. Flexibility and light weight mean that a polybraid hose assembly can more easily accommodate weight and space constraints than most other PTFE hose assemblies.

The inner lining of a tafted PTFE hose extends, in one continuous surface, through the end fitting and over its sealing face. This design ensures that the PTFE lining remains the only internally wetted surface when a tafted hose assembly is operated. This ensures that the tafted hose assembly maintains its physical integrity even when used to transmit aggressive chemicals, including strong acids and alkalis.

The addition of a cover made from vulcanised EPDM rubber increases the ruggedness of PTFE hose assemblies, supporting greater longevity even in harsh external environments. Our specialist team manufactures EPDM rubber covered PTFE assemblies to order, building each unit to meet specific customer needs.

Accreditations

Certifications